Fidar Faraz Fartak designs and manufactures a full range of high-performance screw air compressors engineered for efficiency, durability, and reliability. Our product line includes belt-driven, direct-coupled, and permanent-magnet motor (PM) models, with both single and double stage airend units, each developed to meet diverse industrial requirements. Every model can be equipped with a Variable Speed Drive (VSD) system, delivering significant energy savings and stable air output under varying load conditions. With advanced engineering, precision assembly, and dust and water protection up to IP54, our compressors offer dependable operation and long service life for a wide range of industries.

Fidar compressors deliver powerful performance and superior reliability across a wide range of industrial applications. Covering capacities from 5.5 KW up to 315 KW, with working pressures of 8, 10 and 13 bar. Backed by our in-house engineering and design team, Fidar Faraz Fartak provides custom-built compressor systems tailored to meet the unique requirements of every client, ensuring optimal performance, energy savings, and long-term dependability.

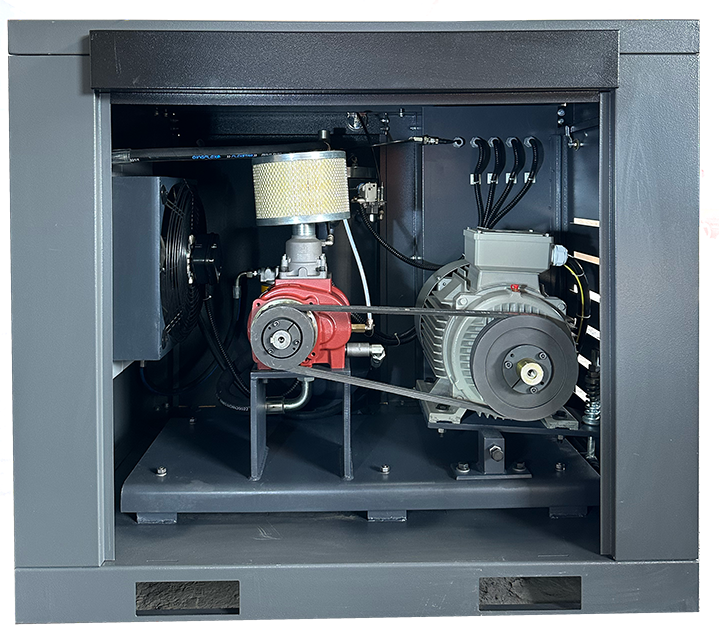

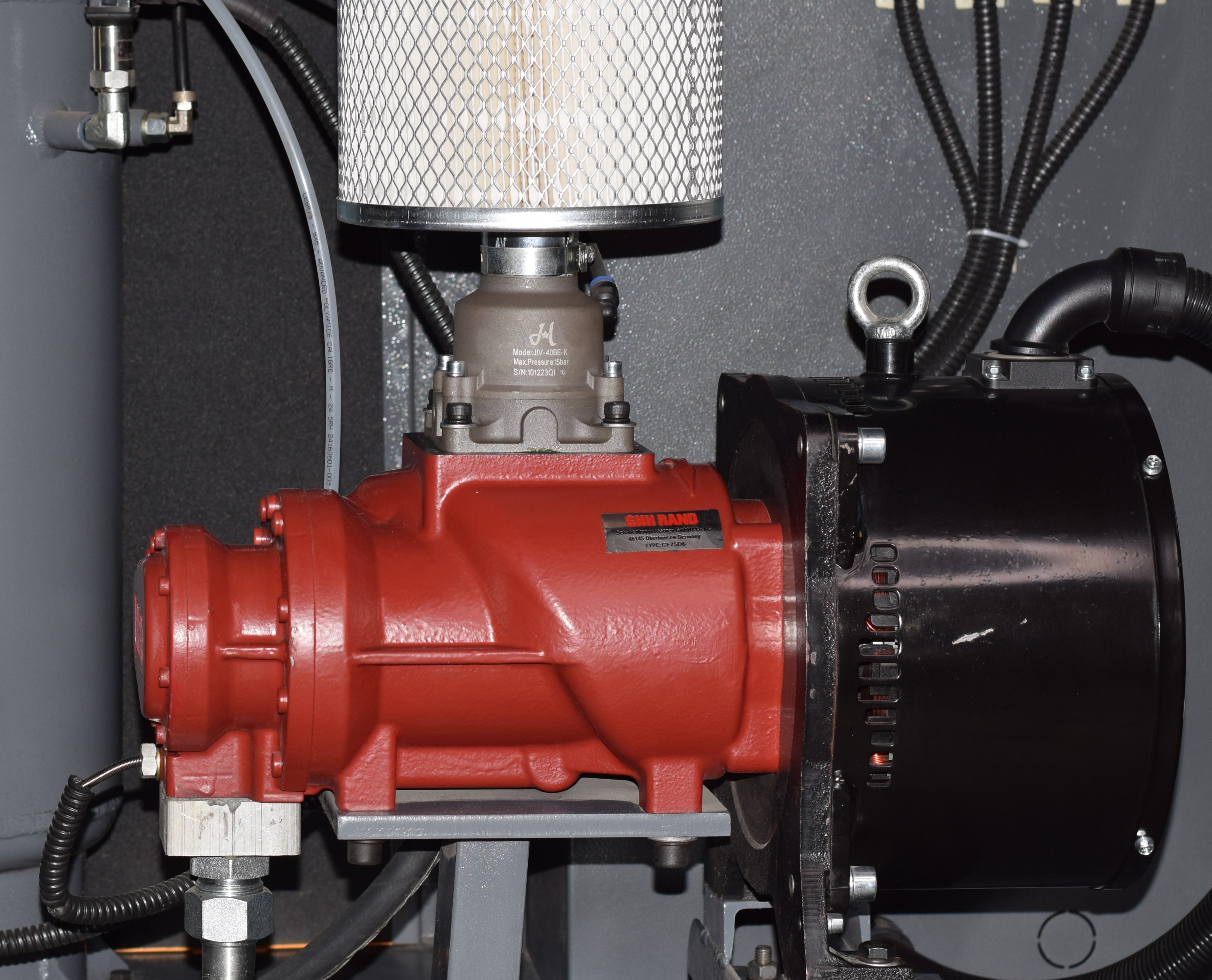

Belt Driven Compressors:

In the design of this type of compressor, the transmission of rotational power from the electric motor to the air-end unit is achieved through balanced Taperlock pulleys made of high-quality cast iron, which represent one of the company’s distinctive engineering features. The pulleys are connected via premium-grade belts, and the rotation of the air-end unit is driven by the electric motor.

Belt Drive System Structure:

- Equipped with an automatic tension adjustment system

- Incorporates a suspension system for vibration damping

- Ensures easy maintenance and component replacement

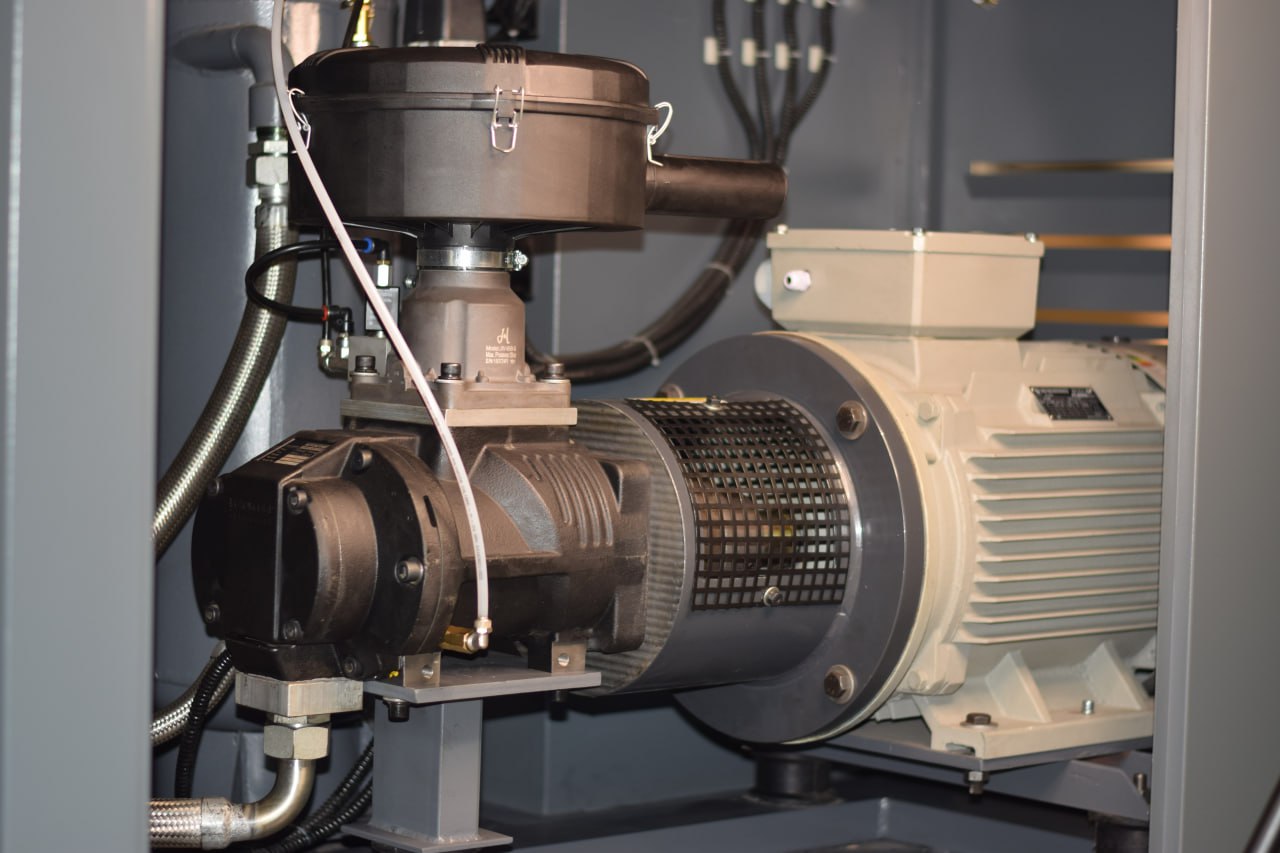

Direct-Driven Compressors (Direct Coupling):

In this compressor design, power transmission is achieved through a direct-drive coupling system, meaning that the electric motor shaft is directly connected to the air-end shaft, allowing torque to be transferred without the use of belts or pulleys.

Key Features of Industrial Rotex Coupling Structure:

- Reduced mechanical losses and improved energy transmission efficiency

- Lower noise and vibration levels generated by mechanical motion

- Elimination of belt adjustment and replacement requirements during operation

- Compact design and high durability, suitable for continuous industrial duty

Taper Connection Mechanism with Magnet Bearing compressors:

The compressor power transfer method is engineered with an advanced tapered connection system using a magnetic bearing, allowing the airend shaft to be directly integrated into the PM motor. As a result, torque is transferred with maximum efficiency and reliability—eliminating traditional mechanical components (belts, pulleys, couplings), reducing maintenance, and increasing overall system efficiency.

Key Features of Industrial taper connection Structure:

- No pulleys or couplings

- Higher power transfer efficiency

- Lower heat generation

- Lower noise level

Detailed infromation, air delivery and specs are available in our general cataloge

For Technical Consultation and Pricing

Please contact us through the following channels:

Phone: +982182802290

Email: info@fidarcompressor.com